Process Scale-up - Colorobbia Consulting

Main menu

Process Scale-up

Colorobbia Consulting

Ce.Ri.Col. Colorobbia Research Centre

Process Scale-

• Process optimisation

Ce.Ri.Col. extends the product development to the industrialization by optimising the production process in terms of use of raw materials, system set-

•

Thanks to the partaking in national and international projects, Ce.Ri.Col. has also been able to develop innovative scale-

Today the facilities allow to analyse and scale-

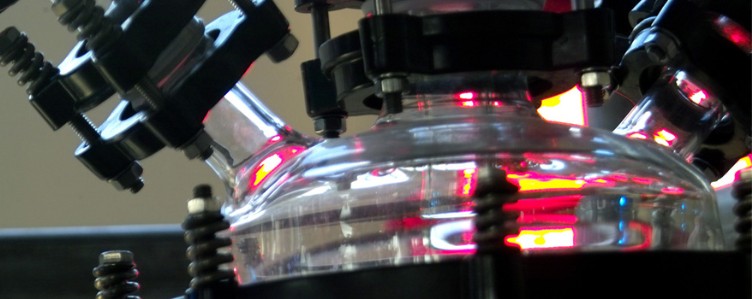

Traditional Glass reactors and continuous Microwave reactors can be used, thus enabling large productions in limited spaces. Thanks to this Ce.Ri.Col. is more and more a research partner capable of industrialize the developed product. The daily output can reach up to 100 L/g depending on the type of material.

• Production process

After scaling-

•

Innovative Materials among which the Nanomaterials of Parnasos series, ceramers and polymeric glasses, are mainly used for multifunctional coating. These products can be applied through traditional techniques such as: dip coating or screen printing or spray gun, to different substrates: glass, ceramic, fabric, metal and plastic surfaces, so as to obtain smart surfaces whose functional properties (anti-